- Services

- Markets

-

Products

- Hydraulic Brakes

- Hydraulic Power Units

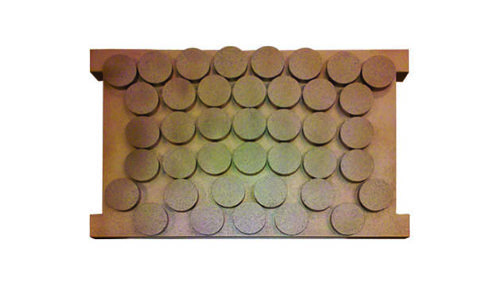

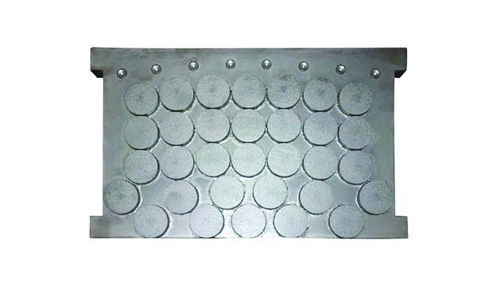

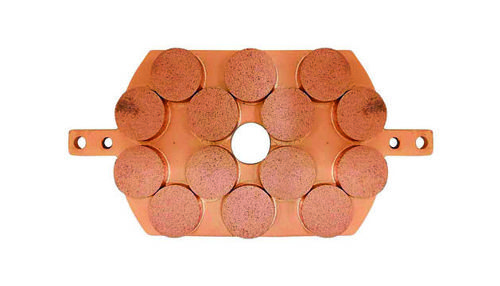

- Brake Pads

- Connectivity

- Braking Controls

- Cooling Systems

- Couplings

- Yaw Systems

- Thruster Brakes

- Rotor Locks

- Storm Brakes

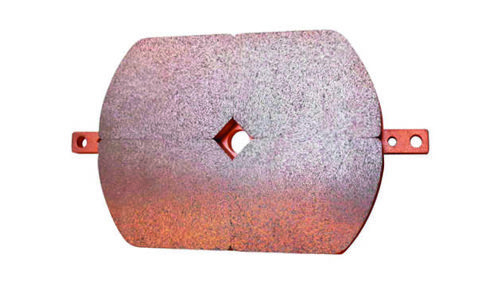

- Brake Discs

- Service Tools

- Spare Parts

- Company